In the intricate landscape of firearm reloading, where precision and safety intertwine, Hodgdon reloading data has become a cornerstone for countless enthusiasts and professionals alike. Yet, beneath the allure of seemingly authoritative load recipes lies a web of potential pitfalls—dangerous mistakes that, if overlooked, can compromise safety and performance. Understanding the nuances of Hodgdon's data, its proper application, and the common errors that lurk within is not just advisable but essential for anyone committed to responsible reloading. This discourse aims to illuminate the critical missteps to avoid when leveraging Hodgdon reloading data, emphasizing the importance of meticulous adherence to guidelines, contextual understanding, and the integration of empirical knowledge for a safer shooting experience.

Understanding Hodgdon Reloading Data: Foundations and Significance

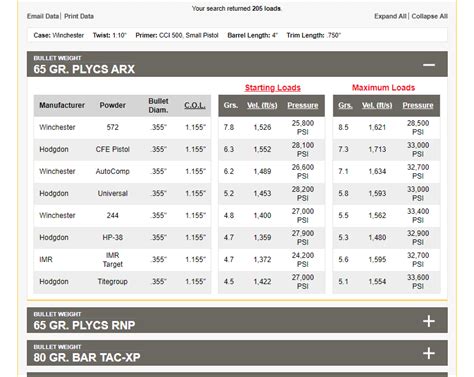

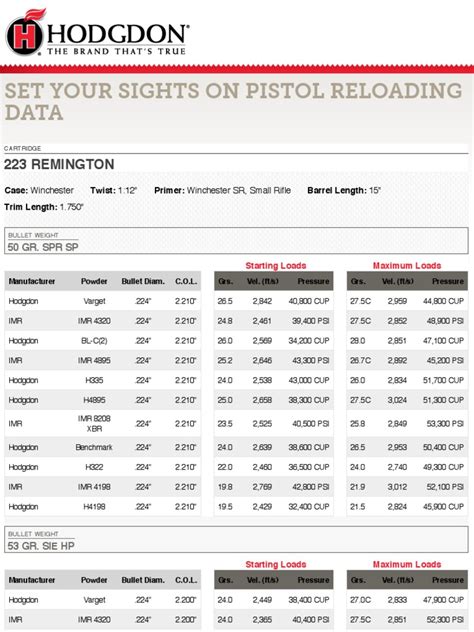

Hodgdon is renowned for its comprehensive and meticulously tested reloading data, published through their annual Reloading Guides and online resources. The data encompasses a wide range of calibers, powders, and bullet types, offering reloaders an invaluable roadmap for achieving peak performance while maintaining safety margins. Crucially, Hodgdon’s data is derived from rigorous testing under controlled conditions, often complemented by extensive field observations. Nonetheless, its application demands careful interpretation, especially since variations in hardware, environmental factors, and individual firearm characteristics can influence outcomes.

Interpreting Hodgdon Data: The Cornerstone of Safety

The core principle when using Hodgdon data is to treat it as a foundation—an excellent starting point rather than an absolute directive. While Hodgdon provides maximum and starting load data, these figures are based on standardized testing and represent safety thresholds rather than recommended maximums. It is vital to understand the context of these loads, including powder manufacturer’s guidelines, projectile specifications, and firearm limitations. Overstepping these boundaries can result in catastrophic failures, such as overpressure conditions, which pose significant risks to shooters and bystanders alike.

| Relevant Category | Substantive Data |

|---|---|

| Maximum Load | Defined as the highest load Hodgdon tested without catastrophic failure, often with a margin of safety, but exceeding this can be dangerous. |

| Starting Load | The load recommended to safely initiate testing, accounting for variation in components and firearm tolerances. |

Common Dangerous Mistakes When Using Hodgdon Reload Data

Despite its authoritative reputation, many reloaders inadvertently commit errors grounded in misinterpretation, complacency, or ignorance of foundational reloading principles. Recognizing these pitfalls is essential for fostering a culture of safety and expertise within the shooting community.

1. Ignoring the Importance of Component Compatibility

One of the most fundamental errors is failing to validate the compatibility of components—primers, cases, bullets, and powders—with Hodgdon’s specified load data. For example, using a different primer brand or size than recommended can alter pressure levels, rendering the data inaccurate. Similarly, case capacity variations among different manufacturers can significantly impact pressure and velocity, making the provided loads unsafe if used indiscriminately.

2. Overreliance on Published Data without Empirical Testing

Overconfidence in published Hodgdon data can foster complacency, leading reloaders to skip incremental testing and validation through chronograph measurements and pressure signs. Each firearm and component batch is unique; thus, starting at the suggested starting load and carefully working up while observing for pressure signs is non-negotiable. Skipping this step increases the risk of overpressure and potential firearm damage or injury.

| Relevant Category | Substantive Data |

|---|---|

| Component Variability | Different brands or lot numbers can vary by 2-5% in case capacity, affecting pressure. |

| Testing Protocol | Incremental load development, usually in 0.5 grain steps, with close monitoring, is vital. |

3. Misapplication of Maximum Loads as Safe Limits

Many shooters mistakenly presume that maximum listed loads are inherently safe for all firearms. This misconception ignores that maximum loads are derived under idealized conditions and do not account for individual firearm tolerances or specific component variations. Push beyond these limits, even slightly, especially without proper validation through pressure testing, introduces the danger of catastrophic failures.

4. Inadequate Data Recording and Documentation

Another critical slip-up involves poor record keeping—omitted data on powder lot numbers, environmental conditions, and chronograph results. Accurate documentation enables pattern recognition of load performance and safety thresholds, allowing for informed adjustments. Without detailed records, optimizing loads and ensuring safety becomes a game of chance rather than science.

5. Rushing the Load Development Process

Impatience can be deadly. Rushing through load development, skipping incremental steps, or neglecting to check for signs of pressure increases elevates the likelihood of dangerous overpressure scenarios. Patience and meticulousness are virtues in responsible reloading; they safeguard lives and extend firearm longevity.

Best Practices for Safe and Effective Usage of Hodgdon Data

To harness Hodgdon’s data effectively while avoiding hazardous errors, several best practices warrant presentation. These stand as the cornerstone of a conscientious reloader’s workflow.

1. Always Start Low and Work Up Gradually

Initiate testing with Hodgdon’s recommended starting load, then incrementally increase load weight, typically in halves—0.2 to 0.5 grains—monitoring each for signs of overpressure, such as flattened primers, sticky bolt lift, or cratered primers. Employing a chronograph to record velocity helps assess consistency and detect anomalies that might indicate unsafe pressure levels.

2. Use Proper Equipment and Maintain Precision

Precision scales, well-maintained reloading presses, and high-quality measuring tools are indispensable. Bolster safety by calibrating equipment regularly and verifying each component’s identity and condition before use.

3. Verify Consistency of Components

Consistent cases, primers, and powders reduce variability, which is essential for safe load development. Keep detailed logs to track component lot numbers and batch-specific peculiarities.

4. Incorporate Empirical Testing and Data Analysis

Chronograph readings, pressure signs, and configuration adjustments are integral to optimized, safe loads. Stay within the parameters established through careful testing rather than relying solely on published maximums.

Summary: Embracing Responsible Reloading with Hodgdon Data

Hodgdon’s reloading data, when employed with respect for its tested boundaries and underpinned by careful empirical validation, forms the backbone of safe and reliable ammunition reloads. Avoiding common mistakes—such as component incompatibility, overconfidence in published data, and rushing procedures—is the key to safeguarding oneself and others. The responsibility to uphold meticulous standards and adapt data to real-world variables underscores the essence of responsible reloading. By integrating a methodical, informed approach, reloaders can elevate their craft, ensuring that their passion for shooting remains both exhilarating and safe.

What are the most common hazards associated with using Hodgdon reloading data?

+The primary hazards include overpressure leading to firearm damage or injury, component mismatches causing unpredictable performance, and rushing the load development process, which increases the risk of dangerous failures if pressure signs are ignored.

How can I ensure my Hodgdon loads are safe?

+Start at Hodgdon’s recommended starting load, incrementally increase while monitoring for pressure signs, use consistent components, chronograph velocities, and document all steps thoroughly. Always verify compatibility and adhere to safety protocols.

Is it safe to exceed Hodgdon’s maximum load data?

+Proceeding beyond Hodgdon’s maximum loads is inherently risky without proper pressure testing and validation. Such practices can lead to catastrophic firearm failure and injury, so it is strongly discouraged unless conducted by qualified laboratories or pressure test facilities.

What role does component variability play in reload safety?

+Variations in primers, cases, and powders can alter pressure levels significantly. Each component lot may behave differently, making it essential to verify compatibility, measure carefully, and adjust loads accordingly to maintain safety margins.